Brush motor working principle

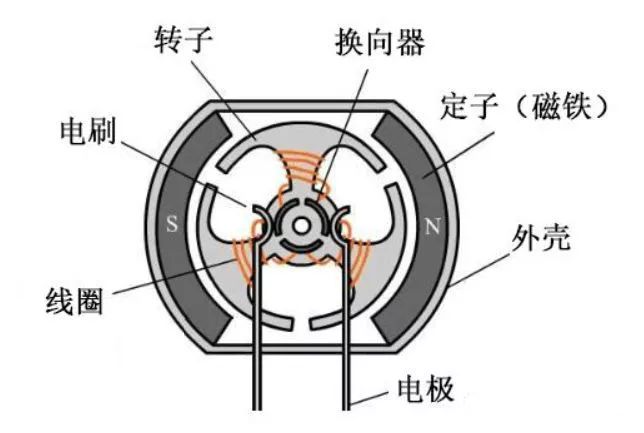

Brush motor is the first type of motor that we have contact with. It is also the model to show the motor introduced in physics class in middle school. The main structure of brush motor is stator + rotor + brush, which can obtain the torque through rotating magnetic field and thus output kinetic energy. Brush and commutator constantly contact friction, in the rotation of conductive and commutator.

Brush motor USES mechanical reversing, magnetic pole does not move, coil rotation. When the motor is working, the coil and commutator are rotating, while the magnetic steel and carbon brush are not rotating. The alternating change of the coil current direction is completed by the commutator and brush rotating with the motor.

In a brush motor, this process is to group the two power input end of the coil, in turn, arranged in a ring, separated with insulating materials between each other, forming a anything like cylinder, become an organic whole repeatedly with the motor shaft, the power supply through the two small pillar made of carbon (carbon brush), under the action of spring pressure, from the two specific fixed position, the pressure on the power input, two points of circular cylindrical coil to coil of a set of electricity.

As the motor rotates, different coils or different poles of the same coil are energized at different times, so that there is a suitable Angle difference between the N-S pole of the coil generating magnetic field and the N-S pole of the nearest permanent magnet stator. The magnetic field attracts and repels opposites, generating force and driving the motor to rotate. The carbon electrode slides on the wire end of the coil, like a brush on the surface of an object, so it is called a carbon "brush".

Mutual sliding, will friction carbon brush, causing loss, the need to replace the carbon brush regularly; Alternating on and off between carbon brush and coil terminal will lead to electric spark, electromagnetic breakage and interference with electronic equipment.

Brushless motor working principle

In brushless motors, commutating is done by the control circuit in the controller (generally hall sensor + controller, more advanced technology is magnetic encoder).

Brushless motor adopts electronic reversing, the coil does not move and the magnetic pole rotates. Brushless motor USES a set of electronic equipment to sense the position of permanent magnet pole through hall element. According to this sense, electronic circuit is used to timely switch the direction of current in the coil to ensure the generation of magnetic force in the right direction to drive the motor. Eliminates the disadvantage of brush motor.

These circuits are the motor controllers. The brushless motor controller can also achieve some functions that the brushless motor cannot achieve, such as adjusting the power switch Angle, braking the motor, making the motor reverse, locking the motor, using the brake signal, stopping the power supply to the motor. The electronic alarm lock on the battery car now takes full advantage of these functions.

Brushless DC motor is a typical mechatronics product, which is composed of motor body and driver. Since brushless DC motor is operated by automatic control, it will not be like the synchronous motor with variable frequency speed under heavy load start on the rotor in addition to the start winding, also will not oscillate and out of step in the load sudden change.

The difference between brushless motor and brushless motor speed regulation

As a matter of fact, the control of both motors is voltage regulation. Only because the brushless DC adopts electronic commutation, it can be realized by digital control. While the brushless DC is commutation by carbon brush, which can be controlled by traditional analog circuit such as SCR, so it is relatively simple.

1, brush motor speed regulation process is to adjust the motor power supply voltage level. The adjusted voltage and current are converted through the commutator and the brush to change the strength of the magnetic field generated by the electrode to achieve the purpose of changing the speed. This process is called variable pressure speed regulation.

2. Brushless motor speed regulation process means that the voltage of the motor's power supply remains unchanged and the control signal of the electrical regulation is changed. The switching speed of the high-power MOS tube is changed by the microprocessor to realize the speed change. This process is called variable frequency speed regulation.

Performance difference

1. Brush motor has simple structure, long development time and mature technology

As early as the 19th century when the motor was born, the practical motor produced was the brushless form, namely the ac squirrel-cage asynchronous motor, which has been widely used after the generation of alternating current. However, asynchronous motor has many insurmountable defects, so that the development of motor technology is slow. In particular, brushless DC motor has been unable to be put into commercial operation. With the rapid development of electronic technology, it has been slowly put into commercial operation in recent years. In essence, it still belongs to the category of AC motor.

Brushless motor was invented shortly after it was born. The brushless DC motor mechanism is simple, easy to produce and process, easy to maintain and easy to control; Dc motor also has a fast response, large starting torque, from zero to rated speed can provide rated torque performance, so once it has been widely used.

2. Dc brush motor has fast response speed and large starting torque

Dc brushless motor has fast starting response, large starting torque, steady speed, almost no vibration from zero to maximum speed, and can drive more load when starting. The brushless motor has large starting resistance (inductive resistance), so the power factor is small, the starting torque is relatively small, there is a buzz when starting, accompanied by strong vibration, and the driving load is small when starting.

3. Smooth operation of dc brushless motor, good starting and braking effect

The brush motor is regulated by voltage, so the starting and braking are stable, and the constant speed operation is also stable. Brushless motor is usually controlled by digital frequency conversion, which first changes AC to DC and THEN dc to AC. The speed is controlled by frequency change, so the brushless motor runs unsteadily during starting and braking and has large vibration. It will be stable only when the speed is constant.

4, DC brush motor control accuracy is high

Dc brush motor is usually used together with reduction gearbox, decoder, so that the motor output power is greater, control accuracy is higher, control accuracy can reach 0.01 mm, almost can let the moving parts stop at any place you want. All precision machine tools are controlled by DC motor. The brushless motor is unstable during starting and braking, so the moving parts will stop at different positions each time. Only by means of locating pin or limiting device can the motor stop at the desired position.

5. Dc brush motor has low cost and convenient maintenance. Due to the simple structure of dc brush motor, low production cost, many manufacturers, more mature technology, so it is widely used, such as factories, machine tools, precision instruments, etc., if the motor fault, just replace the carbon brush, each carbon brush only need a few yuan, very cheap. Brushless motor technology is not mature, high price, limited application range, mainly in constant speed equipment, such as frequency conversion air conditioning, refrigerator, etc., brushless motor damage can only be replaced.

6. No electric brush and low interference

The brushless motor eliminates the brush, the most direct change is that there is no electric spark generated when the brushless motor operates, which greatly reduces the interference of electric spark to the remote control radio equipment.

7. Low noise and smooth operation

Without the brush, the frictional force of brushless motor is greatly reduced in operation, smooth operation and much lower noise. This advantage is a great support for the operation stability of the model.

8. Long life and low maintenance cost

Without the brush, the wear of the brushless motor is mainly on the bearing. From the mechanical point of view, the brushless motor is almost a maintainable motor. When necessary, it only needs to do some dust removal and maintenance.

Brushless motor control principle

Motor drive control is to control the motor rotation or stop, and the speed of rotation. The motor drive control part is also called electronic Speed Controller (ESC). Different motors are used for electric adjustment, which are brushless and brushless.

The permanent magnet of the brush motor is fixed. The coil is wound around the rotor and the direction of the magnetic field is changed by a brush in contact with the commutator to keep the rotor rotating continuously. Brushless motor, as its name suggests, has no so-called brush and commutator. Its rotor is a permanent magnet, while the coil is fixed and directly connected to the external power source. The problem comes. In fact, the brushless motor also needs an electronic governor outside, which is basically a motor drive. It changes the direction of the current inside the fixed coil at any time to ensure that the force between it and the permanent magnet is mutually exclusive and the continuous rotation can continue.

Brush motor can work without the need for electric adjustment, directly supply electricity to the motor can work, but this can not control the motor speed. Brushless motor must have electric adjustment, otherwise it can't turn. It is necessary to convert direct current to three phase ALTERNATING current by brushless modulation (BLDC).

The earliest modulation was not like the current modulation, it was all brush modulation, so you might ask, what is brush modulation and what is the difference between the current brushless modulation. In fact, the difference can be big, brush and brushless electric modulation are based on the motor, now the motor rotor, is able to rotate the part is all magnet block, the coil is the stator does not rotate, because there is no carbon brush in the middle, this is a brushless motor. And brush motor, as the name suggests is a carbon brush, so it is brush motor, like our ordinary children play with one or two dollars of remote control car motor is brush motor. The electric modulation is named after these two types of motors, brushless and brushless. From a professional point of view, brushless modulation is the output of direct current, brushless modulation output is three-phase AC. Direct current is the electricity stored in our batteries, there are positive and negative, our home 220V, used for mobile phone charger or computer power is ac. Alternating current is with a certain frequency, generally speaking is a line of positive and negative, positive and negative back and forth exchange; Direct current is the positive electrode is the positive electrode and the negative electrode is the negative electrode. Ac and DC figure it out, so what is "three-phase electricity"? Theory says three-phase alternating current is a transmission form of electricity, referred to as three-phase electricity, is composed of three ac potential with the same frequency, the same amplitude, phase in turn 120 degrees different from each other. Colloquially speaking, it is our household three alternating current, in addition to voltage, frequency, drive Angle different, other are the same, now for three-phase electricity and direct current understand it.

Brushless modulation, the input is direct current, through a filter capacitance to stabilize the voltage. Both of then divided into two road, all the way is electrically controlled BEC use, BEC is for receiver and electrically controlled MCU used in power supply, the output to the receiver of the power cord is the red lines on the line and black line, the other is involved in MOS tube to use all the way, here, the electrically controlled with electricity, SCM started, drive MOS pipe vibration, make motor drops dripping sound. After starting, they will be on standby. Some of them have throttle calibration function. Before entering standby, they will monitor whether the throttle position is high or low or in the middle. After everything is ready, the SCM in the electrical adjustment will determine the output voltage and frequency according to the signal on the PWM signal line, as well as the driving direction and the number of inlet Angle to drive the motor speed, steering. This is the principle of brushless electromodulation. When the drive motor is running, a total of three groups of MOS tube work within electrical modulation, two in each group, the positive output a control, a control negative output, when the positive output, negative output, not negative, the output of the output is highly, it has formed an alternating current, also, to do this work, three groups of their frequency is 8000 hz. At this point, brushless MODULATION is the equivalent of a converter or governor used in a factory motor.

The input is direct current, usually powered by a lithium battery. The output is three-phase AC and can drive the motor directly. In addition, there are three signal input lines, input PWM signal, used to control the motor speed. For model aircraft, especially quadcopter aircraft, due to its particularity, it needs special mode electric adjustment.

So why do you need special electrical modulation on a quadcopter, what's so special about it? The quadcopter has four OARS, two of which are in a crosswise structure. In the paddle on the steering and reverse, which can be offset by a single blade rotation caused by the spin problem. Each oar has a small diameter, and the centrifugal forces of the four OARS are dispersed as they rotate. Unlike a straight propeller, only one can generate concentrated centrifugal force to form the inertial centrifugal force of gyroscopic properties, keeping the fuselage from turning over quickly. So the usual steering gear control signal update frequency is very low.

Four axis in order to quick response, in response to postural changes caused by drift, need high speed electric adjustable, the renewal speed of conventional PPM electrically controlled only about 50 hz, doesn't satisfy the need that control the speed, and PPM electric control MCU built-in PID, can the speed change characteristics of conventional model aircraft to provide smooth, on four axis is not appropriate, four axis motor speed changes in need is a quick reaction. With high-speed special electrical adjustment, IIC bus interface transmission control signal, can reach hundreds of thousands of times per second motor speed changes, in the four-axis flight, attitude time can remain stable. Even if suddenly attacked by external forces, still unharmed.